Almost half (48%) of firms globally will overhaul their entire procurement and supply chain strategy in the case of a prolonged Covid-19 crisis, according to a survey.

The global survey of around 400 procurement, supply chain and operations executives – by consultancy Kearney in collaboration with the World Economic Forum – found 44% were adapting transportation methods to ensure continuity of supply while 40% were prioritising orders for critical facilities and vulnerable customers.

The poll – which examined supply chain resiliency – found nearly two-thirds (63%) of executives in the UK scored their organisations just 4.8 out of 10 for adaptation.

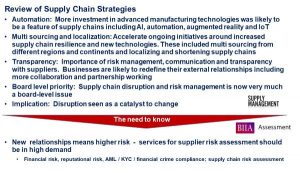

Nigel Pekenc, principal at Kearney, told SM the results suggested the pandemic would accelerate ongoing initiatives around increased supply chain resilience and new technologies. These included multi sourcing from different regions and continents and localising and shortening supply chains.

“With over 75% of the world’s manufacturing output being directly affected by the crisis, the impact on value chains, which are more global and interconnected than ever before, only serves to amplify and prolong the effects of the pandemic and the inability of value chains to respond in the agile way required during such extreme disruption,” he said.

Priorities mentioned by interviewees included the importance of risk management, communication and transparency with suppliers, and keeping people safe while ensuring supply. Some respondents reported being caught out by the speed with which the pandemic took hold, and the lack of any specific preparation plans.

Priorities mentioned by interviewees included the importance of risk management, communication and transparency with suppliers, and keeping people safe while ensuring supply. Some respondents reported being caught out by the speed with which the pandemic took hold, and the lack of any specific preparation plans.

The research found UK businesses were taking a number of different measures, including protecting suppliers by offering purchase guarantees (69%), supporting suppliers with an analysis of risks for certain components (43%), and shutting down non-essential facilities to free up national energy and infrastructure resources (40%).

More investment in advanced manufacturing technologies was likely to be a feature of supply chains including AI, automation, augmented reality and IoT, according to Pekenc. Businesses are also likely to redefine their external relationships including more collaboration and partnership working.

Alex MacPherson, director of solution consultancy and account management at software provider Manhattan Associates, said innovation and flexibility were key to organisations surviving the pandemic. “The organisations that have done relatively well are the ones that have been innovative, flexible and agile,” he told SM. He said for the next year or so firms would reduce inventory. “I think people will be reluctant to have large stock holdings,” he said.

MacPherson said concerns in the warehousing sector about labour constraints, due to Brexit, had been “slightly diminished” by the pandemic and furloughs. He said there was a question around how long the changes brought about by lockdown would last. “Will people go back to the norm quite quickly or will what has changed stay? I think things will go back to the norm more than people think.”

Claire Milner, senior VP of EMEA business at software firm Kinaxis, told SM: “Across the industry, supply chain disruption and risk management is now very much a board-level issue. “Many are seeing this disruption as a catalyst to change and are coming to terms with the fact that, while disruption is  not always of this degree, it is a normal part of the supply chain, and measures must be in place to minimise the impact going forward.”

not always of this degree, it is a normal part of the supply chain, and measures must be in place to minimise the impact going forward.”

Source: Supply Management