Supply chain disruptions including Covid-19 and geopolitical tensions cost US and European businesses up to $4tn in 2020, a report has found.

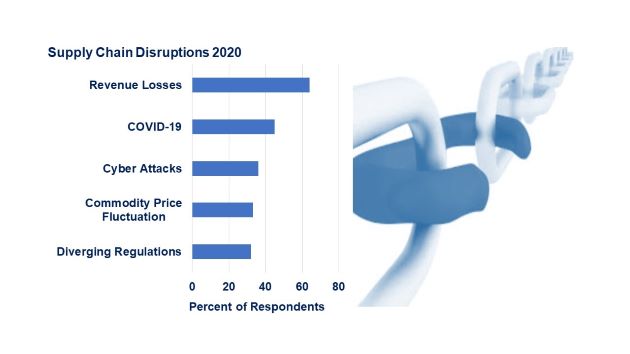

The report, by GEP (Supply Chain & Procurement), found almost half (45%) of firms said Covid-19 “significantly” disrupted their supply chain, but other challenges impacting firms included cyber attacks (36%), commodity pricing fluctuations (33%), and diverging regulations (32%).

In a survey of 400 C-suite executives at European and US global companies, 64% reported revenue losses between 6% and 20% in 2020, which GEP calculated to be as much as $4tn.

Around 38% of firms with revenue greater than $1bn said there had been “significant damage to company’s brand reputation” as a direct result of supply chain disruptions. A third (33%) added disruption meant their “operational costs increased”.

The report said supply chain disruptions were expected to become more common. Geopolitical risks such as regional trade policy, instability, and corruption were many firms’ biggest concern, above rising labour costs in supplier countries.

Continued disruption has led firms to undergo a “major shift in strategy”, GEP said. Around 60% of respondents said “redundancy and resilience in their company’s supply chain are more important than speed and efficiency”.

“Companies are pursuing a range of actions to mitigate the impacts of future disruptions, including strengthening relationships with existing suppliers, implementing permanent supply chain risk management teams and processes, accelerating investment in digital technology, and integrating supply chain and procurement more closely with finance and IT,” the report said.

John Piatek, GEP’s vice president, consulting, said: “While Covid-19, understandably, gets all the press, it is far from the only force wreaking havoc with the world’s global supply chains that costs most companies double-digit revenue loss and, perhaps more important, immeasurable reputational damage and customer loyalty.

“Supply chains and procurement are a key driver of sustainable competitive advantage, but despite spending millions on ERP solutions, most global companies are ill-equipped to effectively manage complex global supply chains in the face of uncertainty, global warming, tariffs and trade wars, and national governments’ increasing control of natural resources and strategic industries.”

Source: CIPS.ORG/Supply-management